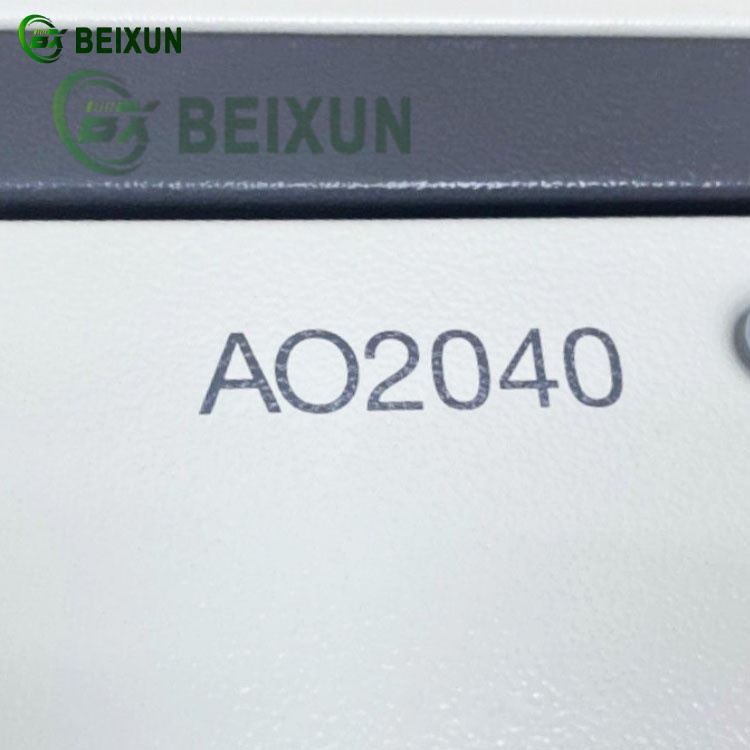

The ABB AO2040 Advance Optima Continuous Gas Analyser (AO2000 Series) is a modular, high-performance gas analysis system designed for industrial process monitoring and environmental compliance.

Its key functions and features include:

Core Functions

1. Multi-Gas Analysis

Supports simultaneous measurement of multiple gases (e.g., O₂, CO₂, CH₄) using configurable modules like laser analyzers, FID (Flame Ionization Detectors), and thermal conductivity sensors.

Enables real-time monitoring with sub-ppm accuracy for trace gas detection.

2. Modular & Scalable Design

Integrates up to 4 analyzer modules and 6 sample components within a single system, allowing customization for diverse applications.

Features hot-swappable modules for maintenance without process interruption.

3. Automated Calibration & Diagnostics

Uses built-in calibration cells or ambient air for automatic calibration, eliminating reliance on test gas cylinders.

Self-monitoring alerts for maintenance needs (e.g., sensor drift, flow anomalies).

4. Technical Features

Hazardous Area Compliance: Certified for ATEX, EAC, and CSA standards (e.g., AO2040-Fidas24 Ex for Zone 1/2/21/22).

Communication Protocols: Ethernet TCP/IP, PROFIBUS, Modbus, and OPC server support for integration with DCS/PLC systems.

Robust Construction: Designed for harsh environments with pressurized enclosures and EMI-resistant components.

5. Applications

Industrial Process Control: Monitoring combustion efficiency in power plants/refineries.

Environmental Compliance: Emissions tracking (e.g., stack gases, VOC leaks).

Safety Systems: Explosive atmosphere monitoring (e.g., oil/gas facilities).

6. Key Advantages

Centralized Operation: Remote control via Ethernet for multi-module systems.

Future-Proof Upgrades: Modular design allows technology updates without full system replacement.

There are no reviews yet.