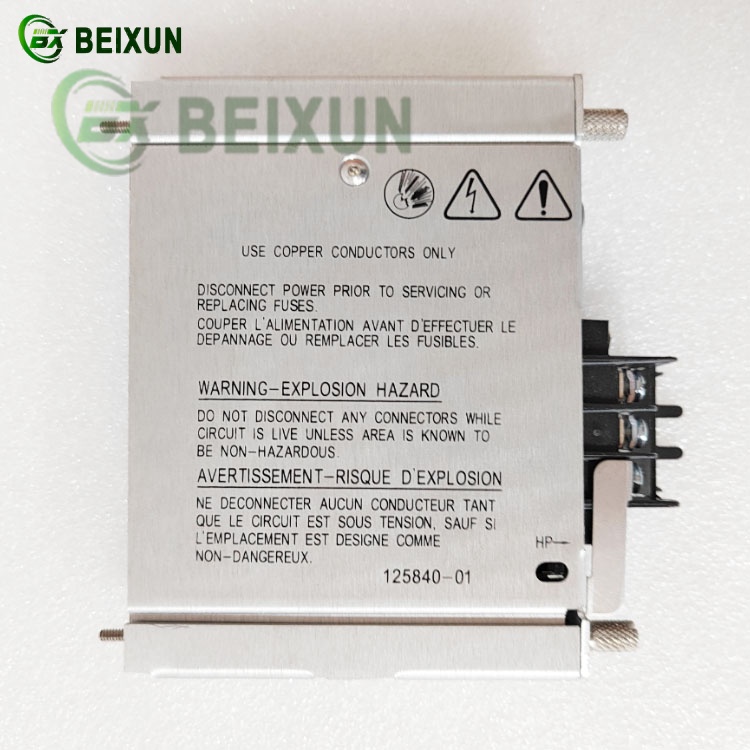

The BENTLY NEVADA 125840-01 Asset Condition Monitoring Module is a critical component in industrial predictive maintenance systems, designed to enhance equipment reliability and operational efficiency.

Its primary functions include:

1. Real-Time Equipment Health Monitoring

Continuously tracks vibration, temperature, and other mechanical parameters to detect early signs of machinery degradation.

Integrates with Bently Nevada 3500 series monitors for comprehensive condition-based diagnostics.

2. Predictive Maintenance & Fault Prevention

Identifies abnormal patterns (e.g., bearing wear, misalignment) to trigger alerts before catastrophic failures occur.

Supports automated shutdown protocols via relay outputs to protect critical assets like turbines and compressors.

3. Industrial Applications

Power generation: Monitors gas/steam turbines and generators to prevent unplanned outages.

Oil & gas: Safeguards pumps and compressors in upstream and midstream operations.

Water/wastewater: Ensures reliability of pumps and motors in treatment facilities.

4. Key Features

Multi-protocol communication: Supports Modbus TCP/IP, Ethernet, and Profinet for seamless DCS/PLC integration.

Modular design: Hot-swappable for minimal downtime during maintenance.

Rugged construction: Operates in harsh environments (-30°C to +65°C).

This module enables data-driven decision-making, reducing maintenance costs and extending asset lifespans.

-480x480.jpg)

There are no reviews yet.