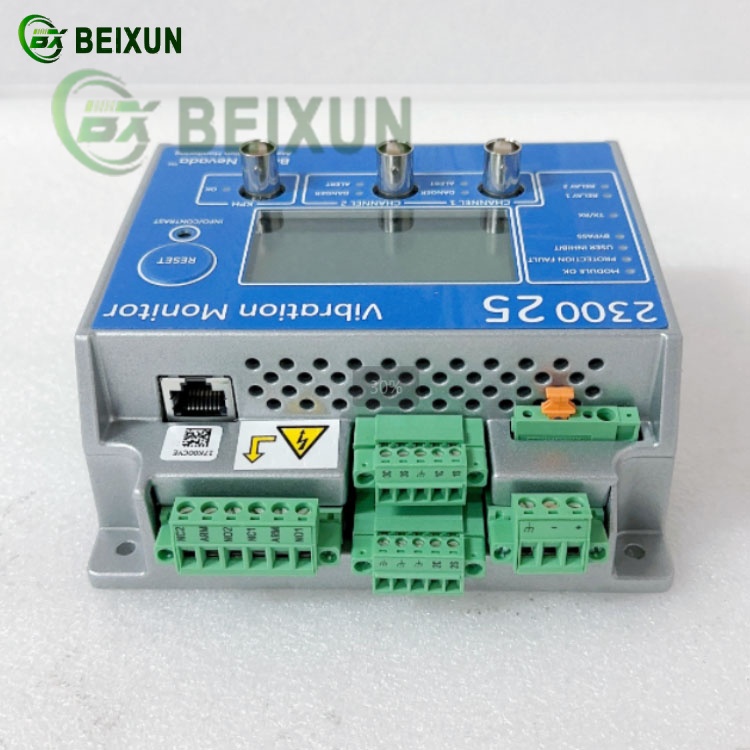

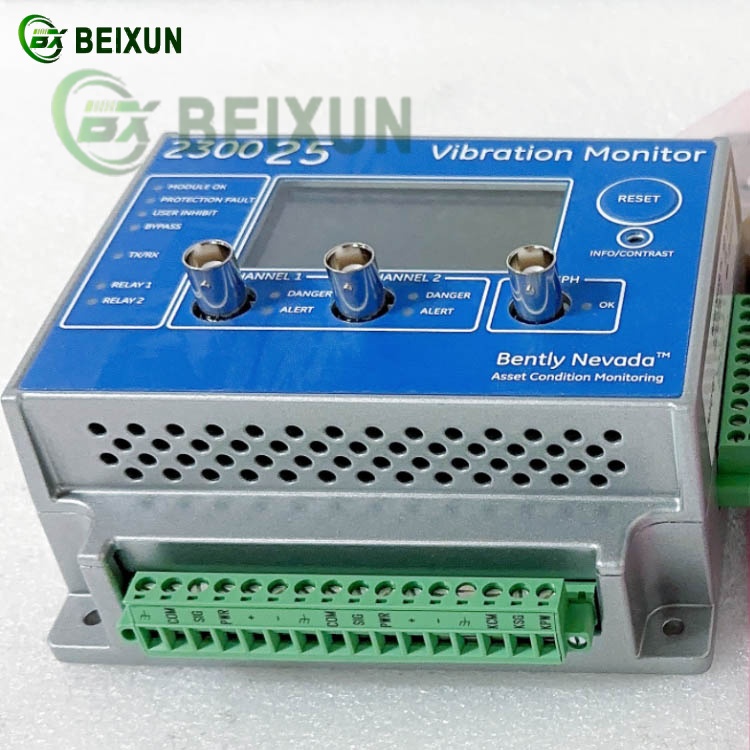

The BENTLY NEVADA 2300/25-00 Vibration Monitor is a dual-channel device designed for machinery condition monitoring and protection in industrial applications.

Here are its key functions and features:

1. Core Functions

Vibration Monitoring:

Continuously measures vibration signals from accelerometers, Velomitor® sensors, or proximity probes (e.g., for shafts/bearings).

Supports time-synchronous measurements via a dedicated speed input channel.

Alarm & Protection:

Triggers relay outputs for high-vibration alerts (configurable setpoints) to prevent equipment damage.

Provides 4-20 mA analog output (2300/20 variant) for integration with DCS/PLC systems.

Condition Monitoring Integration:

Features System 1 Classic connectivity for data analysis via Trendmaster® SPA interface.

Enables predictive maintenance through real-time vibration trend analysis.

2. Key Features

Dual-channel design: Monitors two independent vibration points simultaneously.

Wide compatibility: Works with ICP accelerometers, eddy-current probes, and magnetic pickups.

Industrial durability: Operates in harsh environments (-30°C to 65°C).

3. Applications

Power plants: Turbine/generator monitoring.

Oil & gas: Pump/compressor protection.

Manufacturing: Motor/gearbox health assessment.

This monitor ensures cost-effective protection for medium-to-low criticality machinery across industries.

There are no reviews yet.