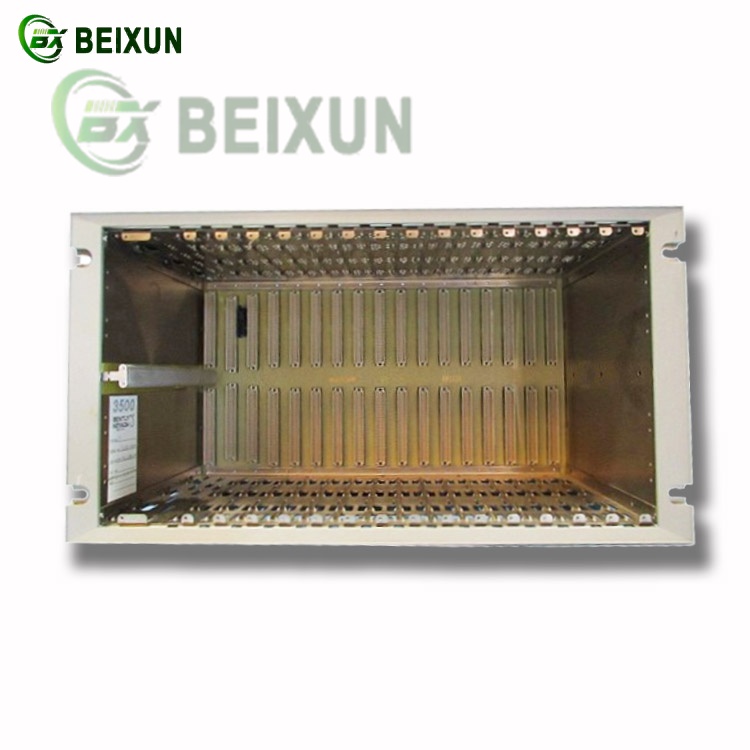

Bently Nevada 3500/05 System Rack

1. Overview

The Bently Nevada 3500/05 System Rack serves as the central housing unit for the 3500 Machinery Protection System, providing power distribution, module communication, and mechanical support for monitoring modules.

It is designed for industrial condition monitoring of critical rotating equipment like turbines, compressors, and pumps.

2. Key Functions & Features

Module Integration & Communication:

Houses up to 14 modules (full-size rack) or 7 modules (mini rack), including vibration monitors, relays, and communication gateways.

Facilitates inter-module communication via a backplane for coordinated machinery protection.

Power Distribution:

Supports dual redundant power supplies (3500/15 modules) for uninterrupted operation.

Converts input voltage (e.g., 175–264V AC) to DC outputs (+8.5V, +21V, etc.) for module operation.

Flexible Installation:

19-inch EIA standard (full-size) or 12-inch (mini) configurations.

Supports panel mounting, EIA rail mounting, or wall mounting.

Industrial Reliability:

Complies with EN 61000-4 (EMC) and NEMA 4/4X (environmental protection).

Operates in harsh conditions (e.g., oil/gas, power plants).

3. Applications

Machinery Protection: Integrates with 3500 series modules (e.g., vibration, temperature) for real-time monitoring.

Condition Monitoring: Connects to System 1® software for predictive maintenance.

Industrial Automation: Interfaces with DCS/SCADA via communication modules (e.g., 3500/92).

4. System Components

Required Modules:

Power Supply (3500/15): Installed in the leftmost slots.

Rack Interface Module (3500/20/22M): Manages backplane communication.

Optional Modules: Vibration monitors, relays, etc..

-480x480.jpg)

There are no reviews yet.