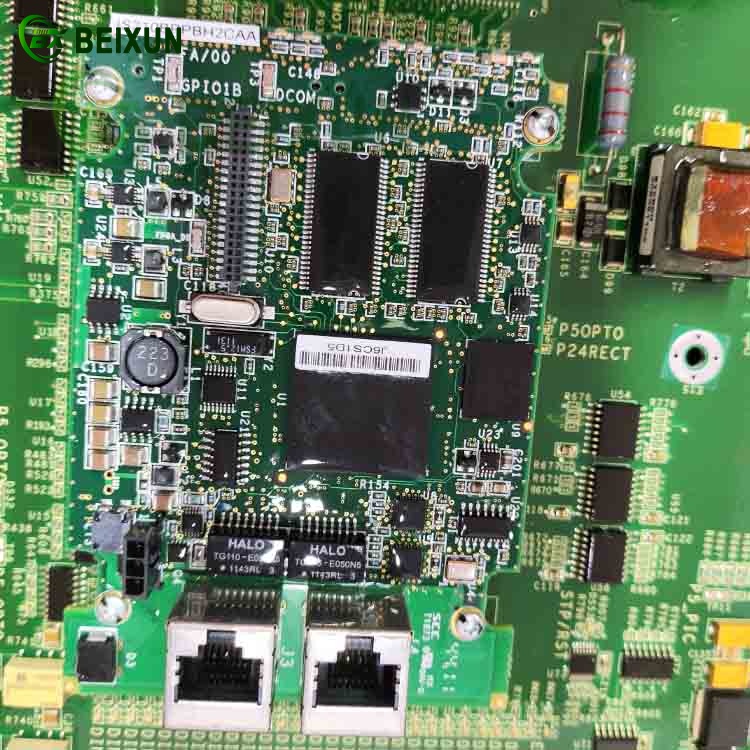

The GE IS200WEMAH1ACA is a circuit board designed for the Mark VI Turbine Control System, a widely used platform for gas/steam turbine management in power generation and industrial applications.

Below is its role and functionality in English:

1. Function & Purpose

Analog & Digital Signal Processing: Acts as an I/O (Input/Output) module, handling analog (e.g., 4–20 mA, 0–10 V) and digital signals between field sensors/actuators and the Mark VI controller.

Signal Conditioning: Filters, amplifies, or isolates incoming signals to ensure accuracy and protect the control system from electrical noise or surges.

Communication Interface: Facilitates data exchange between the turbine control system and external devices (e.g., HMIs, PLCs) via protocols like Ethernet or proprietary GE networks.

Redundancy Support: May integrate with redundant systems to ensure fail-safe operation in critical turbine applications.

2. Key Features

Modular Design: Hot-swappable for easy maintenance without turbine shutdown.

LED Diagnostics: Status indicators for power, communication, and fault detection.

Environmental Robustness: Rated for industrial conditions (temperature, vibration, EMI resistance).

Compatibility: Works within the Mark VI system, pairing with other boards (e.g., IS200-series I/O packs).

3. Typical Applications

Monitoring turbine parameters (speed, temperature, pressure).

Controlling fuel valves, actuators, or auxiliary systems.

Integrating protection logic (e.g., overspeed trips, flame detection).

There are no reviews yet.