The GE IS200WETAH1AEC Interface Board PCB is a critical component in GE’s Mark VI/Mark VIe turbine control systems,

primarily serving as an I/O interface module for industrial automation and power generation applications.

Below is its detailed role and functionality in English:

1. Core Functions

Signal Interface & Distribution:

Acts as a terminal interface board, facilitating connections between field devices (sensors, actuators) and the Mark VI/Mark VIe control system.

Routes analog/digital signals (e.g., 4–20 mA, 0–10 V) for monitoring and control purposes.

Signal Conditioning & Isolation:

Provides electrical isolation to protect sensitive control logic from field-side noise or surges.

May include filtering or amplification circuits to ensure signal accuracy.

Modular Integration:

Designed for hot-swappable replacement, minimizing turbine downtime during maintenance.

Compatible with other Mark VI/Mark VIe I/O modules (e.g., IS200-series).

Redundancy & Diagnostics:

Supports redundant configurations for fail-safe operation in critical turbine systems.

Features LED indicators for real-time status monitoring (e.g., power, faults).

2. Key Features

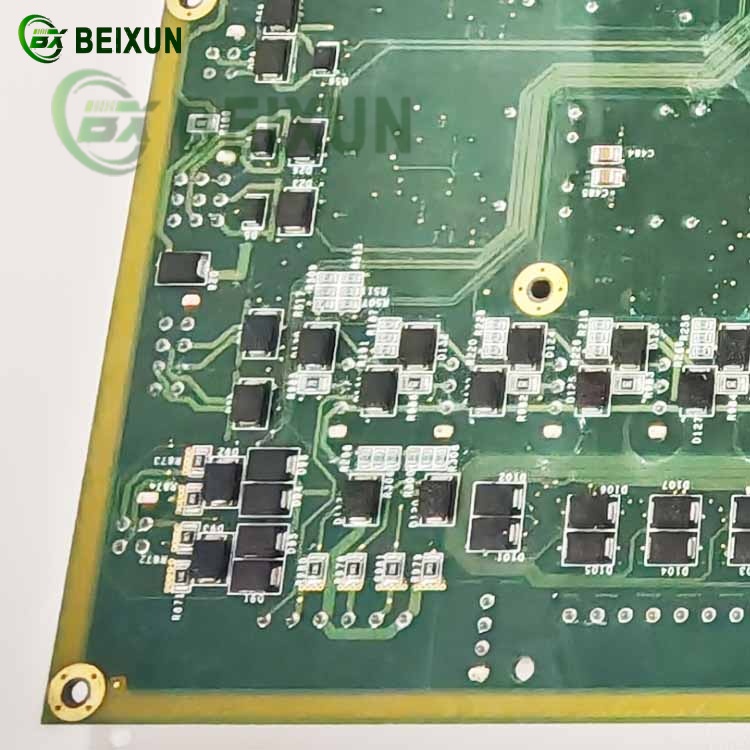

Industrial Robustness: Rated for harsh environments (temperature, vibration, EMI resistance).

High-Density Terminals: Multiple channels for efficient signal termination.

Standardized Form Factor: Easy integration into GE’s turbine control racks.

3. Typical Applications

Gas/steam turbine control systems (e.g., speed, pressure, temperature monitoring).

Power plant automation (e.g., valve control, alarm tripping).

Industrial process control with analog/digital I/O requirements.

There are no reviews yet.