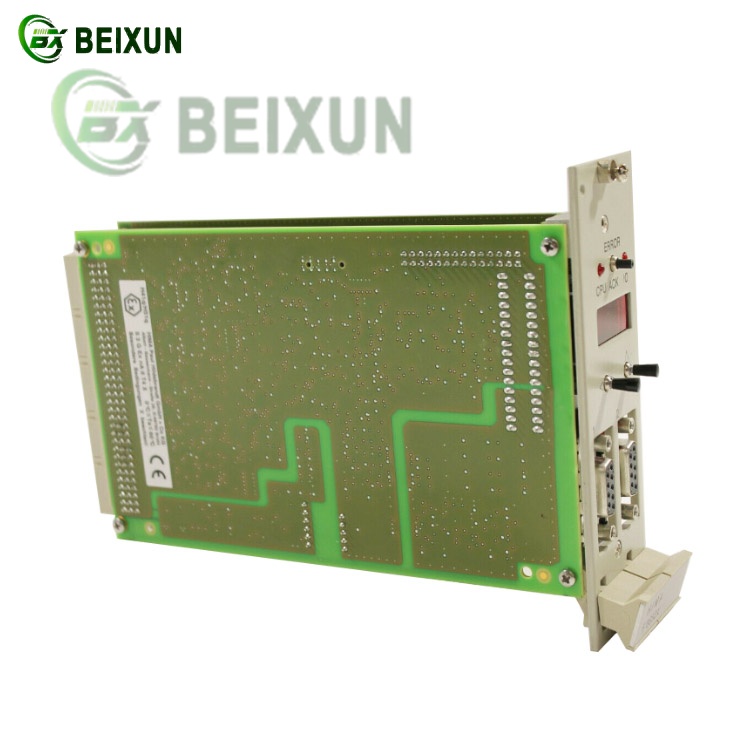

HIMA Central Module F8652X DCS System Module: Core Roles

The HIMA F8652X serves as a central processing unit (CPU) in Distributed Control Systems (DCS), integrating safety-critical control and communication functions for industrial automation environments.

Below are its primary roles and technical highlights:

1. Core Functions

Centralized Control & Monitoring

Acts as the central logic hub for DCS, coordinating inputs/outputs from sensors, actuators, and safety devices (e.g., emergency shutdown systems) to execute control algorithms.

Supports real-time diagnostics via a 4-digit matrix display and LED indicators, enabling rapid fault detection (e.g., CPU errors or I/O module failures).

Safety-Critical Operations

Complies with SIL standards (Safety Integrity Level), ensuring fail-safe shutdown protocols during critical incidents (e.g., overvoltage, equipment malfunctions).

Features a failsafe watchdog with a 24V DC output (500 mA capacity) to maintain system stability during power disruptions.

Communication & Integration

Provides dual RS-485 serial interfaces (electrically isolated) and supports EtherNet/IP, enabling seamless integration with PLCs, HMIs, and SCADA systems.

Compatible with multi-protocol networks (e.g., CAN bus), facilitating interoperability across heterogeneous industrial devices.

2. Hardware Specifications

Processors: Dual Intel 386EX 32-bit microprocessors (25 MHz clock speed)

Memory: 1 MB Flash-EPROM for OS, 1 MB for user programs, 1 MB SRAM for data storage

Redundancy: Dual-CPU architecture with synchronized operation for fault tolerance

Power Supply: 5V DC input (2000 mA consumption) with short-circuit protection

3. Applications in DCS

Process Automation: Manages analog/digital I/O signals for temperature, pressure, and flow control in chemical plants or refineries.

Emergency Shutdown Systems (ESD): Triggers safety protocols (e.g., isolating pipelines) during critical alarms.

Robust Data Handling: Processes large-scale sensor data for predictive maintenance and quality assurance tasks.

4. Key Advantages

Flexible Programming: Customizable logic using HIMA-specific software, adapting to diverse safety and control requirements.

Modular Design: Supports hot-swappable I/O modules, minimizing downtime during maintenance.

Long-Term Reliability: Operates stably in harsh industrial environments (e.g., extreme temperatures, vibration).

The HIMA F8652X DCS Module combines dual-processor redundancy, SIL-compliant safety logic, and multi-protocol communication to serve as the backbone of industrial DCS networks.

Its ability to synchronize real-time data processing, fault diagnostics, and emergency protocols ensures uninterrupted operation in critical infrastructure (e.g., power plants, oil/gas facilities).

There are no reviews yet.